Products

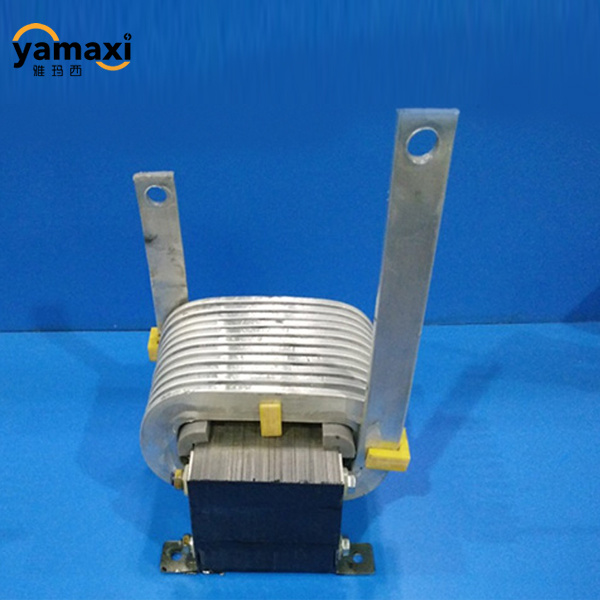

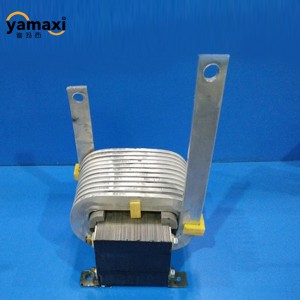

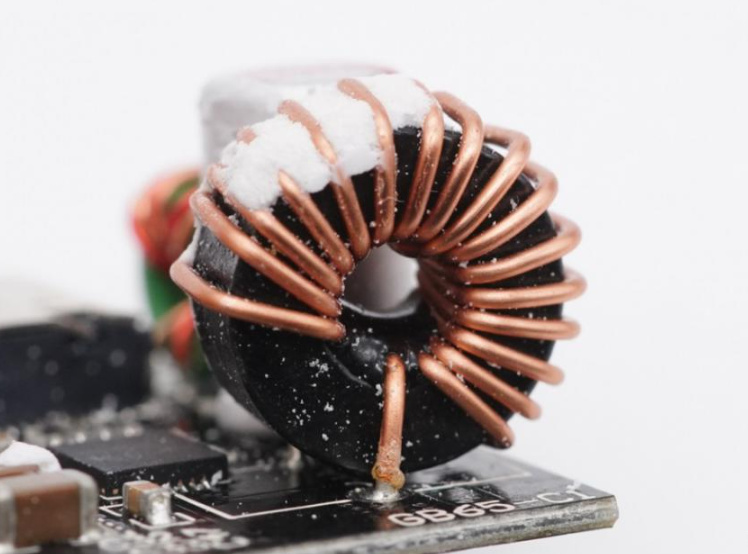

Buck Inductor (Step-down Voltage Converter)

Buck inductor is an electronic component whose main function is to decrease the input voltage to the desired output voltage which is opposite to boost inductor.

The detailed advantages are shown in below:

(1) Small volume, small thickness, in line with the modular development trend of power supply.

(2) Flat vertical winding with good electromagnetic coupling, simple structure, high production efficiency and good consistency of parameters.

(3) Because flat copper wire is mostly used, skin effect can be overcome, resulting in high working frequency and high power density, with the frequency between about 50kHz and 300kHz.

(4) Excellent heat dissipation characteristics, small components with a high surface area to volume ratio and a very short heat channel, convenient for heat dissipation.

(5) High efficiency, the magnetic core structure of the special geometric shape can effectively reduce the core loss.

(6) Small electromagnetic radiation interference.

(7) Uniform distribution parameters;

(8) Fully automatic production, high cost performance.

1. Good dynamic characteristics. Because the internal inductance is small, the electromagnetic inertia is small, and the response speed is fast (the switching speed is on the order of 10ms). It can meet the short-circuit current growth rate when used for flat characteristic power supply, and it is not easy to produce excessive short-circuit current impact when used for down characteristic power supply. The output reactor is not only used for filtering. It also has the function of improving dynamic characteristics.

2. Good control performance. It can be controlled with a very small trigger power, and a variety of external characteristics can be obtained through different feedback methods. The current and voltage can be adjusted uniformly and quickly in a large range, and it is easy to realize the compensation of the network voltage.

3. Compared with DC arc welding generators, it is energy-saving, material-saving and less noise.

4. The circuit is more complicated and uses more electronic components. It is often used for the poor quality of the electronic components or assembly quality, which leads to the failure of the welding machine and reduces the service life.

The reactor of the DC welding machine mainly plays the role of filtering, so that the welding current is stable, especially in the small current welding, it plays the role of maintaining the arc, and avoiding the welding arc.

It is widely used in various switching power supplies and other electrical equipment to suppress the "pollution" of electrical equipment to the power grid and the electromagnetic interference of the power grid to the equipment.